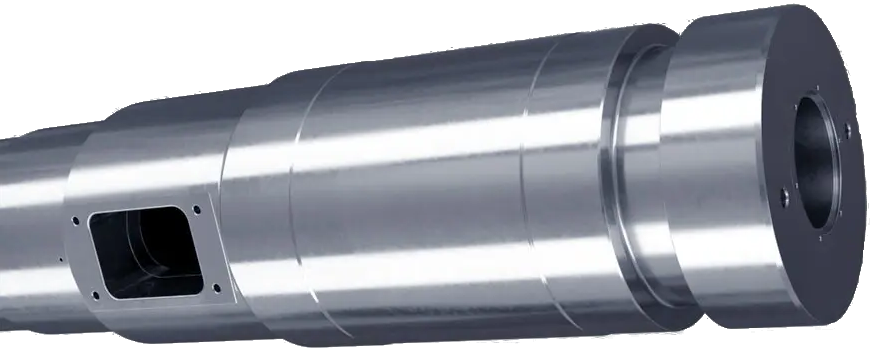

Nitrided & Bimetallic Barrels

Barrels

In the Manufacture of Barrels, we offer several Bimetallic Inlays for types of applications that require:

- Wear Resistance

- Corrosion Resistance

- Extreme Wear & Corrosion Resistance.

For your current Barrel, Resleeving and Honing are offered for cost-effective ways to improve productivity. Inspections need to be performed to determine if these are options that will improve your current application.We offer high performance barrel construction options for corrosion and abrasion wear process environments. Upon application review, our technical sales staff carefully selects the optimum barrel bore compatible with the feed screw, resin, and application process.

A bimetallic cylinder commonly referred to as a barrel consists of two different metals bonded together. The ID liner is a metallic alloy designed to form a hard abrasion and corrosion wear resistant liner. The liner is uniform down the length of the cylinder bore. It is precision honed to a close tolerance fit between the feed screw outer flight land diameter and the barrel ID. The outer backing steel material is constructed from high strength steel alloys. Liners are bound into the ID through centrifugal casting, sintering and interference fit methods. When required Injection barrels are fitted with high-pressure sleeves at the discharge end.